- Have Any Question?

- (+880) 017238012739

- enviroco@gmail.com

SPORT AND TOURISM

WELCOMING AND HOSPITALITY OF THE HOTEL SYSTEM.

We are optimistic that the hotel business will be able to adopt a whole new concept linked with green solutions and environmental responsibility.

That is why ANECO®'s solution, Aneco®, is frequently utilized in a wide range of hotel applications to provide clean water, microbe- and bacteria-free surroundings and facilities, and, most significantly, chemical-free entertainment venues.

Aneco® may be utilized in both hot and cold water systems, as well as open and closed systems. It is a very effective, adaptable, and cost-effective method of ensuring that high sanitary standards are maintained at a hotel.

What exactly is this new philosophy?

The capacity of the hotel business to adapt to new and environmentally friendly end-to-end solutions allows the entire facility to minimize the use of hazardous chemicals in all applications, from water treatment to interior cleaning, without increasing prices or upgrading treatment facilities.

By “end-to-end," we mean applications that span the whole facility, from drinking water purification to wastewater disposal to chemical-free solutions in kitchens, restaurants, conference centers, laundries, swimming pools, and guest rooms.

Previously, hotels saw fit to increase environmental consciousness by altering just specific items and procedures that represented them.

Green goods or solutions are frequently overlooked because they are prohibitively expensive, and if the expenses do not immediately affect the consumer, hotel companies face considerable profit decreases.

ANECO® has succeeded in offering a complete and ecologically safe solution that substitutes several chemicals at significantly lower rates, removing the need for the purchase or storage of any other product by uniting the great powers of science and nature.

What makes this possible?

ANECO®'s solution is the result of superior engineering that generates two unrivaled products from the electrolysis of water and salt within the facility.

ANECO®'s environmentally protective systems divide water and activate solutions to create an exceptionally effective oxidant stream for disinfection in a variety of applications (Aneco®), while the antioxidant stream is utilized for cleaning and degreasing in a variety of applications (Cateco®).

These products can replace up to 80% of the present chemicals purchased for the full hospitality facility's operation. Because of the product's high water content, there is no detergent residue on surfaces, as is common with outdated chemicals that are still in use today.

Traditional residual products serve as a haven for dirt and bacteria.

The product contains 99.69% water. It may be consumed or spread in the environment, has no negative effects on humans or the environment, and yet kills viruses and bacteria.

APPLICATIONS IN THE HOTEL INDUSTRY

Chores around the house

Staff must often carry at least seven or eight chemicals as well as numerous instruments for each product. This has been reduced to three easy-to-carry items, as well as the most recent cleaning equipment, with the introduction of ANECO® solutions.

Water

Disinfection of all effluent water, both inside and outside, without the use of hazardous chemicals.

Laundry

ANECO® products can be used to substitute hazardous chemicals in the in-house laundry service, such as stain removal, sterilization, and bleaching. These dangerous compounds no longer need to be exposed to employees.

ANECO® also works in conjunction with conventional wash powders to minimize volume and expense.

Kitchens and food preparation

ANECO® products may be used to degrease as well as sterilize all surfaces, appliances, and hands. ANECO® systems are completely food safe, and they are also used on food goods to extend the shelf life and freshness of items ranging from meats to vegetables to fruits. The degreasing product can be used with natural oil-based solutions to create a powerful degreasing solution.

Other applications:

– Replace chlorine in hot tubs and small or large swimming pools;

– Disinfect saunas;

– Flush filter systems to improve filtration and media life;

– Replace alcohol disinfection in spas;

– Improve hygiene and odor in gyms;

– Disinfect playgrounds and toys;

– Disinfect and degrease air conditioners;

– Eliminate moss and fungal growth;

– Degrease grills;

– Improve irrigation water and encourage flora growth.

Disinfect incoming and exiting wastewater without using potentially hazardous chemicals.

WHAT ARE THE PERKS?

We receive more and more specific feedback on the benefits stated by our workers with each new application, and in some cases on a daily basis. To date, the following are the key advantages:

The product is made on-site and controlled by you with our assistance, which means:

– No product or material purchase orders;

– No ordering or receiving chemical stock;

– If you need more products, you make them at no extra expense;

– Saving time, resources/staff;

– No theft.

STRONGER

SAFER

MORE RESILIENT

Another significant benefit is the potential to represent their business as a chemical-free and ecologically safe environment facility:

– Guests will eat, sleep, and bathe in chemical-free environments;

– Food will be prepared with little to no chemical exposure;

– Certified drinking water will be treated with a natural chlorine-like substance;

– Improved food quality, freshness, and safety;

– Ongoing in-house training and development;

– No detergent residue caused by traditional chemical use;

– World-class service agreement (SLA).

We have also allowed customers to create a unique product brand that guests would recognize as a distinguishing quality mark.

FIELDS OF APPLICATION IN THE NAUTICAL INDUSTRY

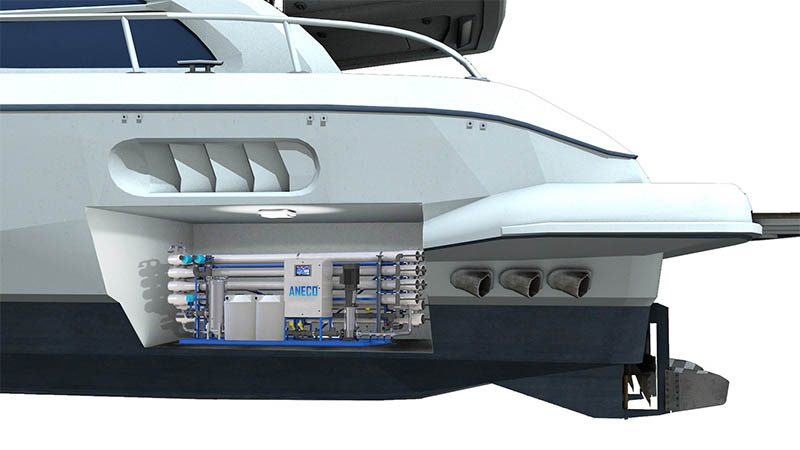

For the industry of unique and exclusive products such as the nautical industry, the small and adaptable application sizes of ANECO® technological systems are perfectly suited to the nautical sector, which sees a wide range of applications for pleasure boats. cruises and commercial boats.

Anti-legionella and potabilization treatments on boats have been tested in cooperation with the “Estensi" shipyards (FE – Italy).

ANECO® products are perfect for the treatment of cold water, domestic hot water and especially drinking water.

Treatment of water in tanks on board with ANECO® products, both natural and ecological, ensures drinking water in the boat and harbor without the undesirable effects of chemicals or similar products on the market. The treatment of wastewater by purification so that it does not have to be returned to the sea, lakes or rivers.

ANECO® products can also be used for boat cleaning, ensuring a more and clean and comfortable environment , whitening and disinfecting living spaces, tanks and cabinets (freezers). In all cases, the reduced-to-zero corrosion characteristics preserve and prolong the life of the materials.

REVERSE OSMOSIS DESALINATION

To meet its customers' desalination needs, ANECO® decided to propose new chemical-free reverse osmosis systems, installed in containers, with a production capacity adapted to the requirements.

THE PRE-TREATMENT PROCESS

Desalination:

Desalination by reverse osmosis must be carried out in order to ensure minimum turbidity conditions and to remove suspended bodies or others (e.g. algae) as well as hard parts (calcium) and metals present in the water.

Filtrations:

For the filtration phase, a series of qwartz filters designed in fibreglass is foreseen.

Pre-feeding pressurisation: Two parallel pumps positioned on the pre-feeding skid « with alternating operation » are provided for pressurisation.

Reverse OSMOSIS desalination

Dopo una prima filtrazione, con filtri di 5 micron che utilizzano cartucce After an initial filtration, with 5-micron filters using PP fibre cartridges, the liquid is sent to the filtration stage on semi-permeable membranes, where the water is pressurised at approximately 64 bar in order to obtain a flow of filtered water. The energy required for the process is supplied by centrifugal or piston-type pressurisation pumps, whose parts in direct contact with the seawater are made of duplex stainless steel, equipped with a state-of-the-art energy recovery system.

Two dosing stations, one for anti-scale and one for antioxidant products, help to preserve the membranes.

All hydraulic components of the high-pressure line are made of duplex steel.

The membrane vessels are made of glass resin (fiberglass) and support a pressure above the expected operating pressure of 64 bar. The low pressure circuit is made of rigid PVC for pressure pipes.

Energy recovery :

The facility is designed with a state-of-the-art energy recovery system that directly transfers energy from the high-pressure concentrate to the salt water equivalent at the inlet.

This technology, combined with membranes that have reduced pressure losses and high-efficiency pumps, offers a significant reduction in energy consumption. This solution guarantees savings of at least 50 per cent of the absorbed electrical energy.

Flow volume:

The volume of the flow membranes will be automatic and programmable with the use of previously osmoticised water. The system includes automatic valves for the correct management of the flow volume, which are in turn controlled by the PLC and with the use of the pre-feed pump, will draw reverse osmosis water directly from the tank.

Management and control :

Il sistema di desalinizzazione dell'acqua è seguito da un quadro elettrico con unità di controllo e gestione “touchscreen" e un modem per il controllo e la programmazione remoto. La strumentazione per il controllo dei diversi flussi e pressioni verrà eseguita con traduttori che consentono la lettura e il tracking digitale.

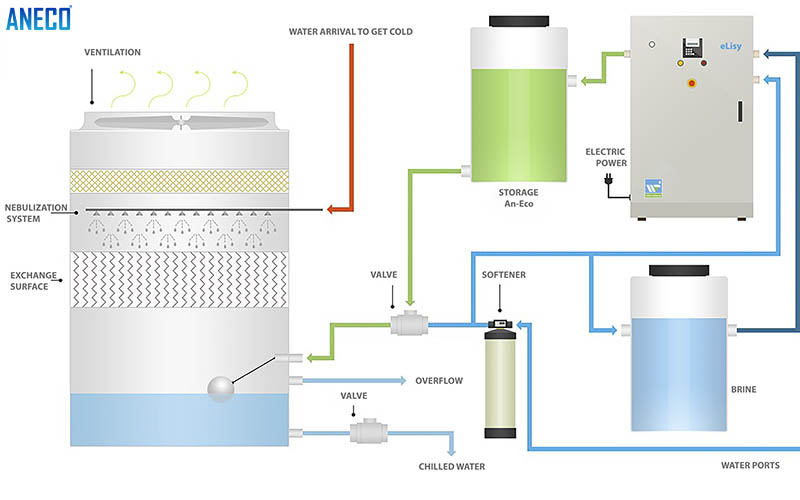

eLisy disinfection system:

The new eLisy water disinfection system allows you to obtain purified and potable water that is perfectly clear, thanks also to an algaecide and floculant action, reducing all types of bacteria, including legionellosis, by 100%.

All 100% natural. eLisy units are designed for cleaning, disinfection and sterilisation systems with 0.05% – 1.0% salt solutions (NaCl or Kcl). The units electrolyse salt water using ceramic or polymer membranes that separate positive and negative ions. The reactions of electrochemistry are the production of different types of active solutions. The purpose is to eliminate pathogens such as bacteria, viruses, spores, moulds and fungi, as well as cleaning and removing certain heavy metals in the water.

The reactions of electrochemistry are the production of different types of active solutions. The purpose is to eliminate pathogens such as bacteria, viruses, spores, moulds and fungi, as well as cleaning and removing certain heavy metals in the water.

In recent years, however, the emergence of multi-resistant bacteria, the discovery of Legionnaires' disease and other problems associated with chlorinated compounds have led to the search for new technologies and ways to disinfect water.

ANECO® technologies have enabled the production by electronic activation of Aneco® (HClO) known to eliminate pathogens; they produce hypochlorous acid also composed of natural sodium hypochlorite ions, with a real reduction in HAZARDS, COSTS and ENVIRONMENTAL IMPACT.

• Easy and safe to use

• Effective: Reduced contact time for sterilisation

• Biodegradable liquids

• Simplifies operating procedures and offers quick and safe benefits.

Aneco®

The strength of Aneco® (HClO) in terms of the concentration of active sodium hypochlorite (chlorine) can be adjusted as required through planned programming in the production machine. A flow regulator is installed in the hydraulic part to stop the eLisy unit in the event of a water shortage and causes the machine to restart when water flow arrives.

An on/off switch, with a power indicator, allows the eLisy unit to be manually stopped or reactivated. There are several basic models ranging from 20 to 10,000 l/h, and the production capacity will therefore vary according to requirements.

The Aneco® (HClO) produced by ANECO® is placed in a storage bin and then injected into the water system as required.

The dosing schedule will depend on the water quality and will be monitored by a flow meter connected to a dosing pump.

Based on extensive studies, the Aneco® solution (HClO) is:

• Environmentally friendly;

• Free of toxicity to humans, animals and nature;

• A powerful biocide;

• Can be safely disposed of in the sewage system;

• Very fast contact biocidal action;

• Can be used in all stages of disinfection and cleaning;

• No waste on any type of surface without a possible recommended dosage;

• Can be applied to liquids, hot or cold, on ice and still in spray form;

• Hypoallergenic;

• Produced on-site, to eliminate storage and handling of chemicals.